floortec

FLOORTEC uncoupling membrane

FLOORTEC uncoupling membrane

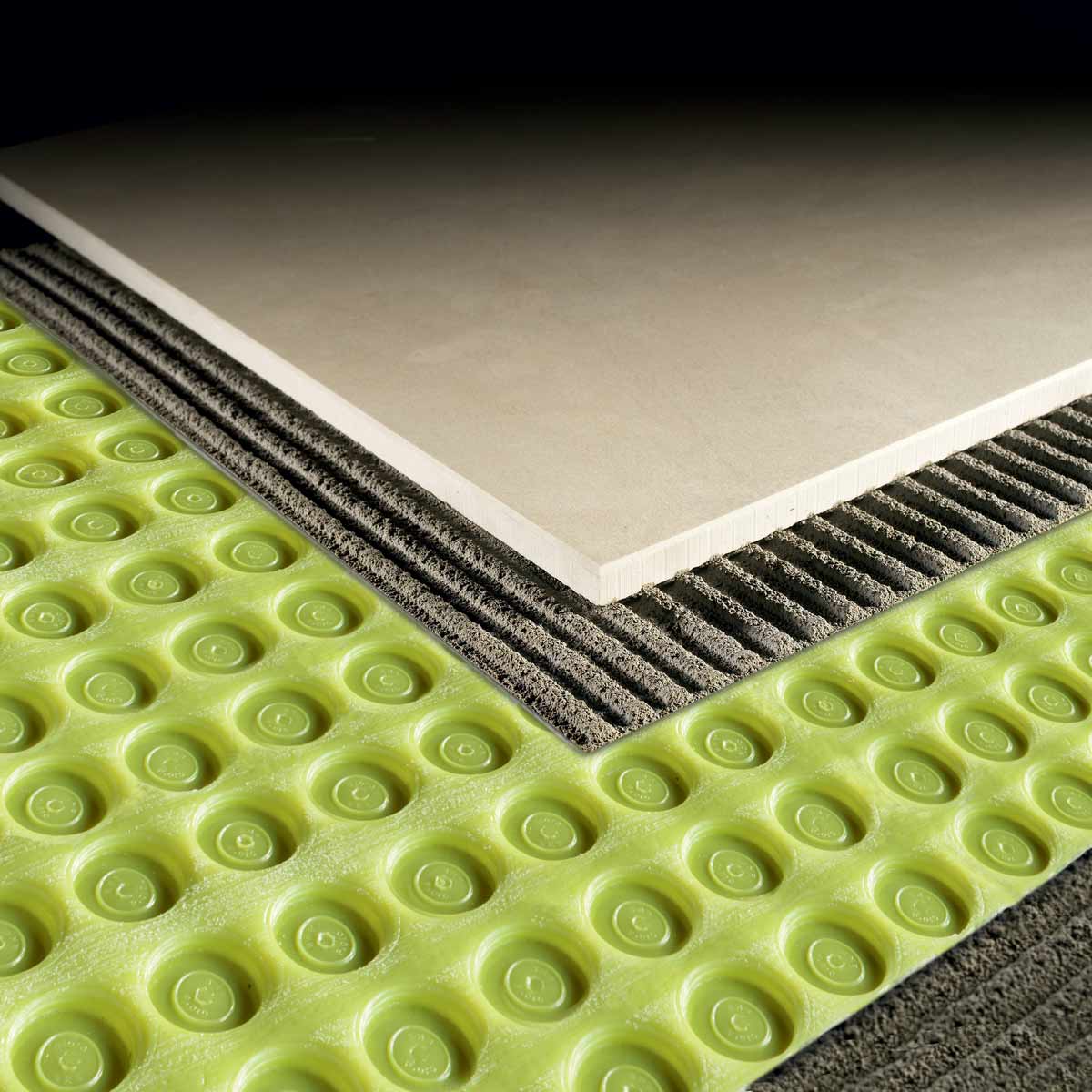

Floortec is an installation membrane for ceramic or stone tile based on uncoupling technology. It is placed between the tile and the substrate. Tile and membrane are bonded using appropriate mortar-based adhesives.

Floortec advantages

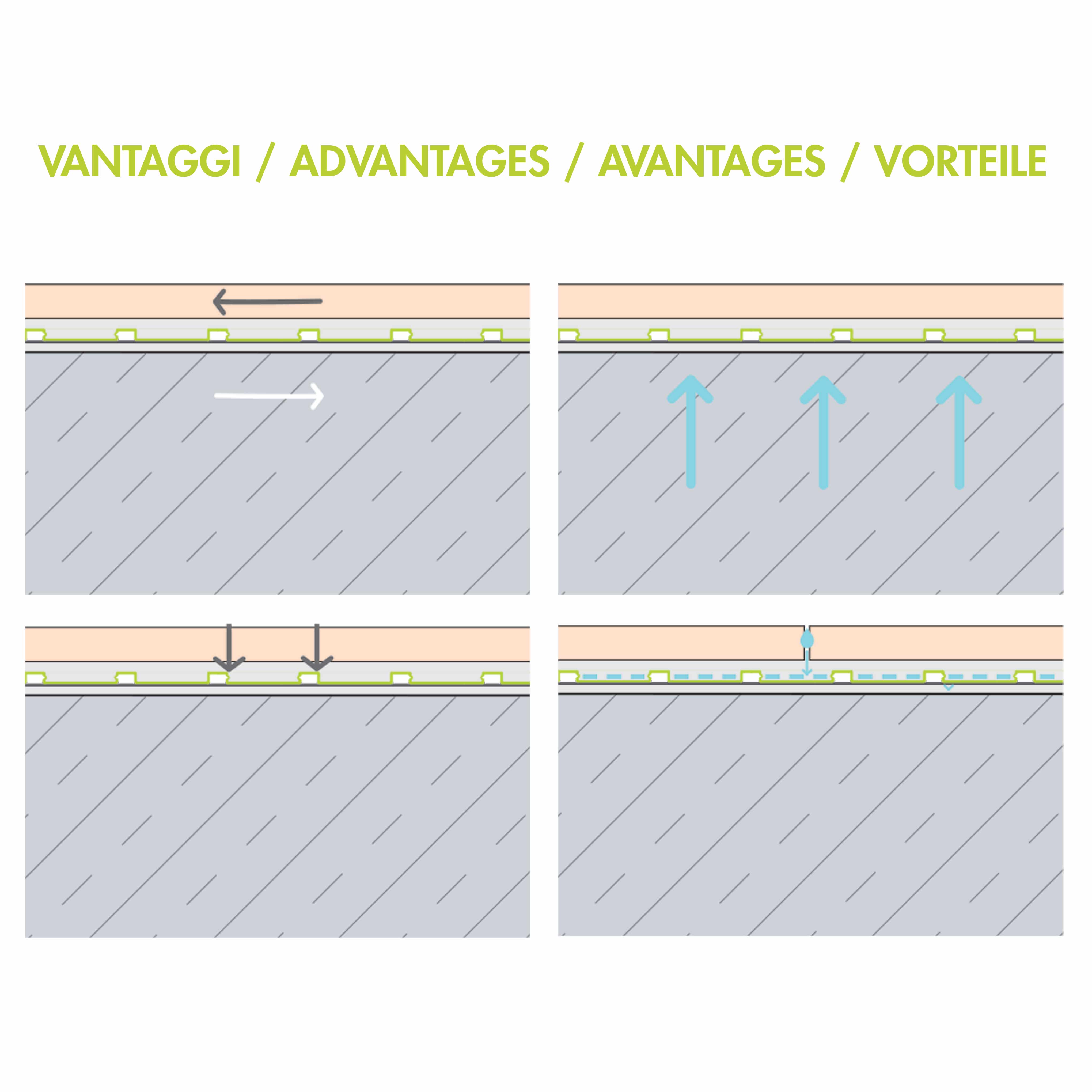

- TENSION COMPENSATION. The membrane is able to compensate for differential movement in all directions, neutralizing tension between the substrate (concrete or wood structures) and tile..

- VAPOR MANAGEMENT. he open cavities on the underside of the membrane provide pressure relief for moisture rising from the substrate allowing the tile flooring to be installed without waiting the usual curing time for concrete (28 days).

- LOAD RESISTANCE. The circular column support structure on the surface of the membrane provides increased load resistance compared to other-shaped columns: the mortar-based adhesive on the surface of the mat fills the circular cavities forming a solid column support structure. FLOORTEC has been tested by TCNA and passed all 14 cycles (Extra-Heavy Commercial) on the Robinson Wheel Test (ASTM C627) over 19.2” wood frame construction.

- WATERPROOFING*. The membrane material, HDPE (high density polyethylene), is waterproof. The top layer of the membrane blocks water infiltration, facilitating the natural water evaporation process. The mortar bed is therefore protected from water percolation and not subjected to damage due to ice formation caused by low temperatures during the winter months.

FLOORTEC membrane installation

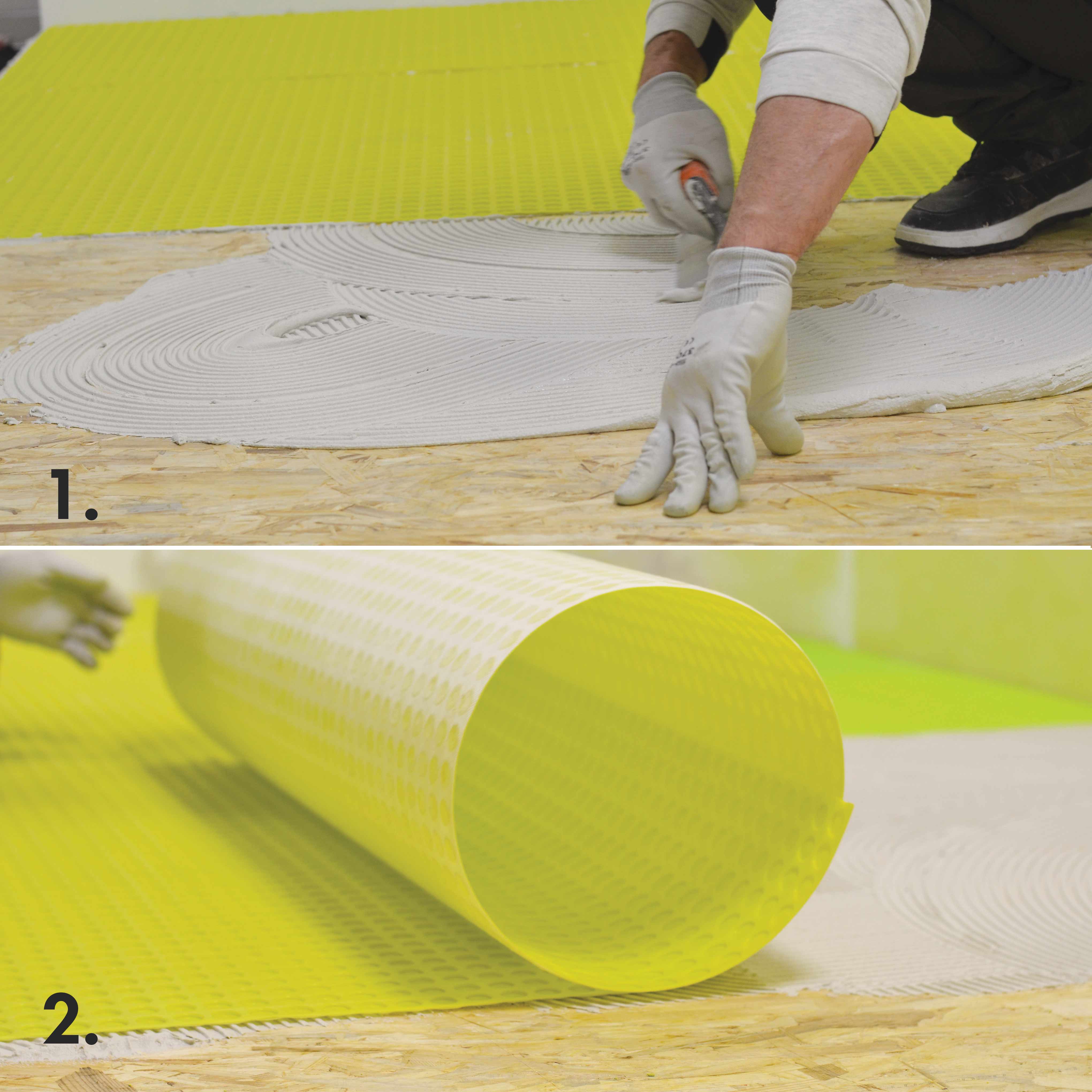

- Cut Floortec membrane to fit area.

- Spread thin-set adhesive to substrate using a ¼” x ¼” square notch trowel.

- Roll out Floortec into adhesive and compress using rubber or wood float.

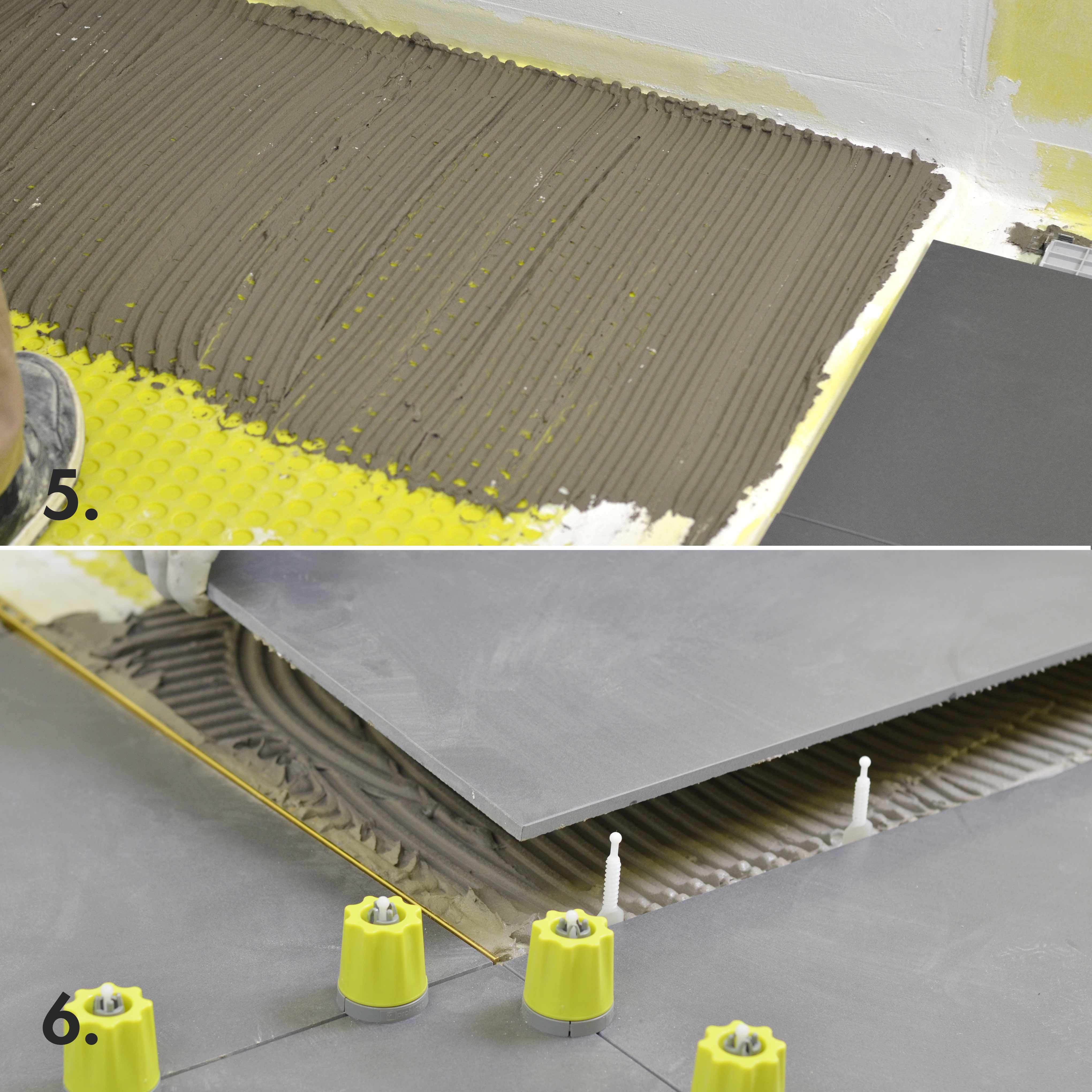

- FOR WATERPROOFING: Apply 6” Foiltec waterproofing strip over Floortec seams and all floor to wall connections using thin-set adhesive applied with a ¼” x 3/16” v notch trowel.

- Apply tile to surface of Floortec using appropriately-sized notch trowel being sure to fill the circular surface cavities.

View more

View less

-

FLOORTEC membrane in virgin polyethylene (PE HD)

High density polyethylene membrane, coupled with TNT (non-woven fabric) on the lower side. Thickness 1/8" - 3 mm on which circular shaped cones are designed which favor the gluing of the tile allowing the glue to adhere better to the membrane. Ideal for laying ceramic floors.

Polyethylene /

H (in) Art. 1/8 FLOORTEC

Select items and add them to the quotation list

Select the models to get a free quote

Select the models to get a free quote

(Reset items)

(Reset items)

Select the product to request a quote

| Article | Material | Finishing | Color | Installazione | H (in) | |

|---|---|---|---|---|---|---|

|

|

Request a quote