Jan 6, 2021

Staff+

The difference between floor and structural expansion joints

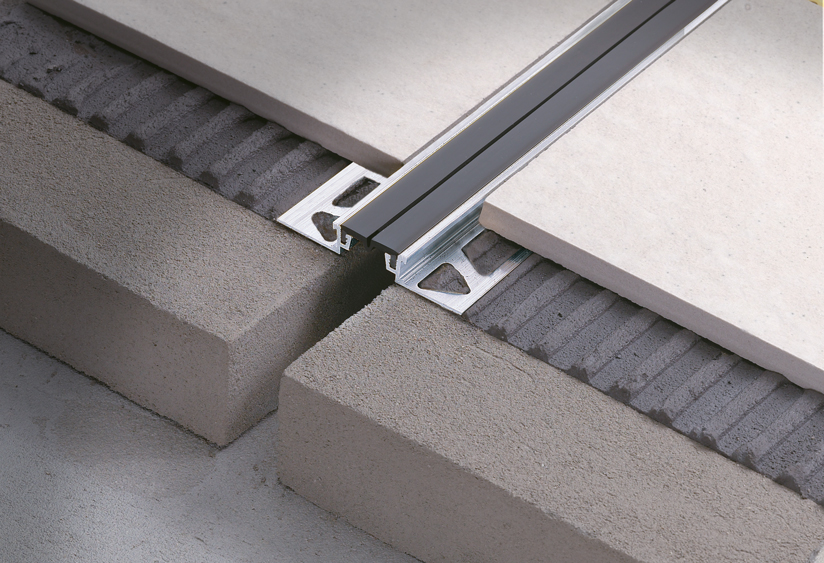

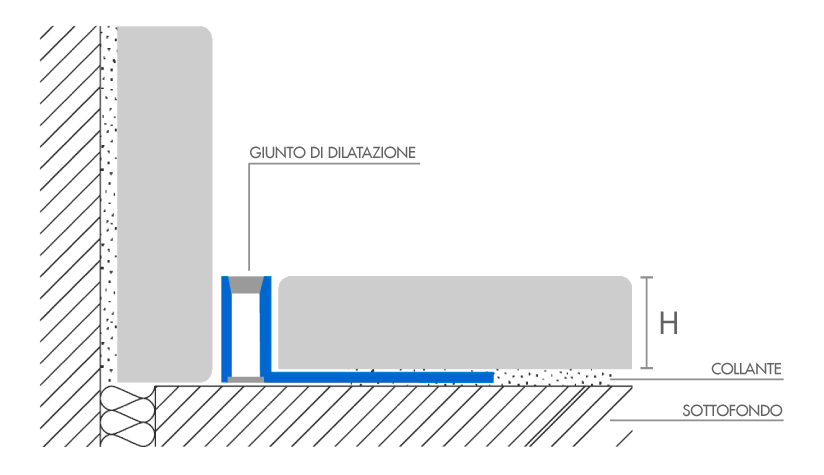

Floor expansion joints are critical technical profiles, they absorb thermal expansions in floors, thus avoiding fractures and positively affecting the quality and duration of the materials installed. Expansion joints only involve the superficial part of the flooring, which is why they are also known as “under tile joints”. However, there are also structural joints, more technical than the previous ones, which also involve the screed, which is why they are often called “under screed joints".

When to use expansion joints

Expansion joints are to be used when the floor exceeds a certain size. The floor shall be divided in smaller areas, creating installation interruptions where the profiles are placed with an elastic insert: these profiles are called expansion joints precisely because they allow the two areas to function, absorbing mechanical stresses between them. It will be necessary to understand with the project manager or the designer exactly where to stop the flooring, and according to the material that will be installed - wood, ceramics, marble, or vinyl - understand what expansions the joint will have to absorb.

Where should a joint be placed?

As a rule, the positioning of the joint should be decided in the design phase or, in case of renovation, before installing the floor. Where?

- Where there is a change in the installation material

- Where there is a new casting

- Where there are pre-existing discontinuities in the substrate, for instance, different screed blocks

- Where there are fixed structural elements, such as doors or columns

- Where there are variations in laying directions

- In potentially fragile areas, like between the floor and the wall

The advantages of correctly positioning the joint in the planning phase

The correct positioning and sizing of a joint is especially important, because:

- it avoids fractures in the flooring

- they influence the quality and duration of the materials installed

- they offer elasticity to the structure by accompanying the movements due to thermal shock: the materials, both superficially and structurally, react to climatic changes and humidity variations with the expansion and reduction of volumes.

How to choose expansion joints

The expansion joint shall be chosen according to the different usages intended for the area and its features, among which:

- Type of flooring (wood and ceramic behave differently in terms of thermal expansion)

- Thickness of the flooring (according to the thickness, pick the correct height of the joint. Note: the joint shall not exceed the edge of the flooring, but rather be 0.5/1 mm lower).

- With stoneware or ceramic tiles, choose the profile according to the size of the tile: the smaller the tile, the lower the mechanical properties of the joint

- Joint thickness

- Type of adhesive(elasticity characteristic)

- Intended use of the area for the type of loads to be supported: pedestrian passage, car traffic, trolleys, etc.

Let’s sum up with concrete examples: for an indoor, domestic environment with tiles up to 30x30 cm, an elastic adhesive and a joint larger than 2 mm, a PVC under-tile joint is suitable, such as Coflex CAJ. It is also called “invisible joint” for its reduced width, 5 mm.

When the joint requires high performance, such as in pedestrian areas and/or with trolleys, for instance, a shopping mall, an aluminum joint with an interchangeable synthetic insert will be more suitable, such as Coflex CB, with a larger width than the previous example.

How are expansion joints installed?

Expansion joints are installed following areas whose side does not exceed 3 m outdoors and 5 m indoors. Here are some installation indications:

- Check that the subfloor is well levelled, without unevenness or hollows

- Use a notched trowel to spread the adhesive in the profile application area

- Cut the profile to size and dip the perforated base in the adhesive

- Add adhesive on the vertical section of the profile

- Leave a gap of approximately 2 mm between the profile and the tile edge to be grouted later

Expansion joint covers for floors

Joint coversare profiles that cover the gaps created in the screed to allow natural thermal expansions and structural movements to avoid cracks in the flooring.

For instance, Copritec CP is also used as a wall protection profile, in hospitals and schools.

Profiles and threshold covers for floors and tiles

For domestic areas and reduced technical needs, we offer threshold cover profiles for floors. For more information visit our blog on floors, section “when to use junction as threshold cover profiles”.

Expansion joints for floors: the different behaviors of wood and ceramics

According to the installation material, the choice of the joint may vary as different materials react differently in terms of thermal expansion. Wood, for instance, may not need high-performance expansion joints thanks to its natural elasticity.

We recommend floor finishing profiles, to absorb limited expansions, which may be chosen according to your needs: threshold covering, transition or perimetral profiles.

Joints for ceramic and stoneware floors

Unlike wood, ceramic is a rigid material. It requires expansion joints to absorb the extension and contraction movements of the structure due to climatic variations and different humidity conditions, as well as seismic movements. Discover our whole range of expansion joints for ceramic floors.

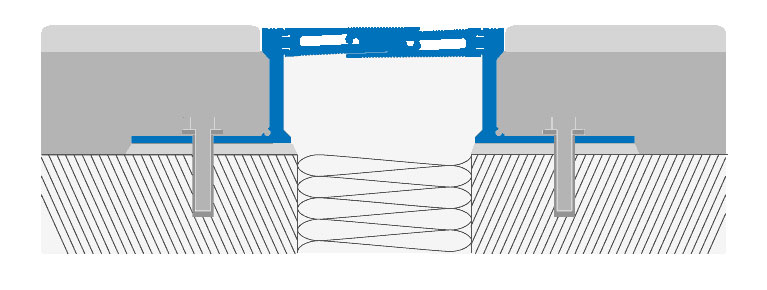

Structural joints for floors

Structural joints for floors are fundamental products to maintain the health of the structure of a building.

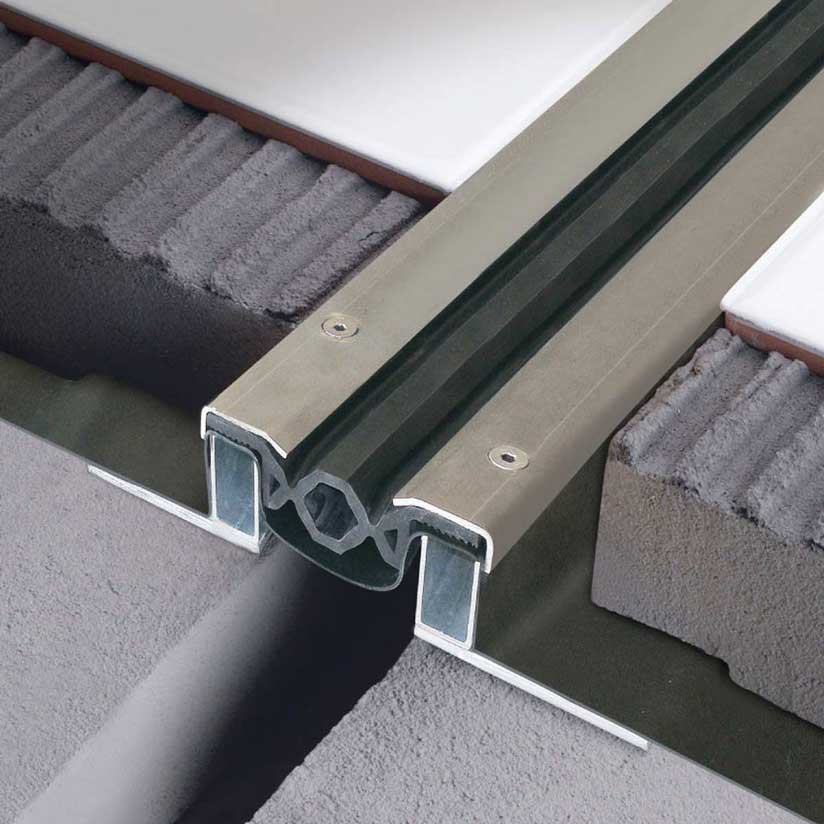

These are more technical products compared with other joints, generally in aluminum or steel, and in considerable size.

They shall be included in the design phase and be placed in openings created in the structure of the building.

Structural joints are also called under screed joints as they affect the floor and screed throughout their thickness. Their width must correspond to the width of the opening created specifically in the structure.

There is a very wide range, which can be divided into two macro families:

-

Aluminum structural joints (for heavy loads such as cars, trucks, pallet trucks), for instance, Jointec GA

-

Structural joints with EPDM insert (excellent mechanical properties, resistance to abrasion and extreme temperatures, perfect for intense pedestrian crossings, as in shopping malls, and car loads. The insert is interchangeable) For instance Jointec GE

-

Structural joints with waterproofing sheath: Jointec GW is a highly technical waterproof profile, made of solid steel, with anti-vibration rubber, continuous stabilized rubber and waterproofing insert.

Vehicle accessible structural joints

Structural joints have high technical performance, and they are vehicle accessible. The best structural joints to this end are made entirely of aluminum and located in the center of the structure (not on the perimeter). Our range includes:

-

Jointec GA for a passage width of 54mm

-

Jointec GH for passage widths of 100, 150 and 200 mm

-

Jointec GAL for a passage width of 86 mm

Among structural joints with insert for forklift passage, we find:

-

Jointec GE for passage widths of 38 and 48 mm

-

Jointec GR for passage widths of 46 and 56 mm

-

Jointec GRM for a passage width of 90 mm

-

Jointec GM for passage widths of 38 and 48 mm

-

Jointec GW for a passage width of 80 mm

-

Jointec GS for a passage width of 100 mm

-

Jointec GD and GDM for passage widths of 40.50 mm or 86 mm

Antiseismic structural joints

These joints allow natural expansions of the structure, thus avoiding cracks and seismic damage. Antiseismic structural joints absorb vibrations caused by ground movements. Our whole range of structural joints contribute to structural stability, find out what is the most suitable structural joint for you!

Joints for industrial floors

Industrial floors are not only used in the production part of companies but also in pharmaceutical, food and hospital environments. These are generally very wide areas, and even an industrial floor, in concrete or resin, needs joints!

Jointec GT is a control joint in rubber, applicable after the installation of the floor.

The surface is cut after the installation is complete and the rubber joint is inserted to guarantee the expansion of the floor. The joint does not extend nor shrink, as it is made of fiberglass. It can be inserted either by hand or, for a faster and more precise application, through a trolley.

For concrete floors, we offer Jointec GC, to be installed simultaneously with the floor. It won’t be necessary to cut the flooring once the installation is complete, as this system is equipped with Jointec GCR joint covers.

In this article, we have analyzed the importance of using expansion and structural joints to overcome serious problems, but if you still have doubts do not hesitate to contact us! Write to us by filling out your request in the form below.

Joints for walls and ceilings

Joints are important not only for positioning in the center of the room but also on the perimeter. The transition between floor and wall is indeed one of the critical areas to manage with perimeter joints: they are always expansion joints placed on the edges of the floor, in correspondence with the wall or with a marble threshold.

See the complete range of perimeter joints.

Coflex CR is a corner profile ensuring the connection between floor and wall. Thanks to its radius of curvature, it is also known as "hygienic shelling", as it is easy to clean.

It is equipped with connection fittings that enable its use also on walls.

The ceiling is also a sensitive area for structural movements. The wall and ceiling joint covers Copritec CPM are used to cover the gap created to allow structural movements.

Comments

There is no comment

Leave a comment

Staff+

Dec 11, 2020

Wooden, PVC or aluminum baseboards? It shall suit your environment

Staff+

Jan 20, 2021