JOINTEC GRM modular structural joints in metal and rubber

JOINTEC GRM modular structural joints in metal and rubber

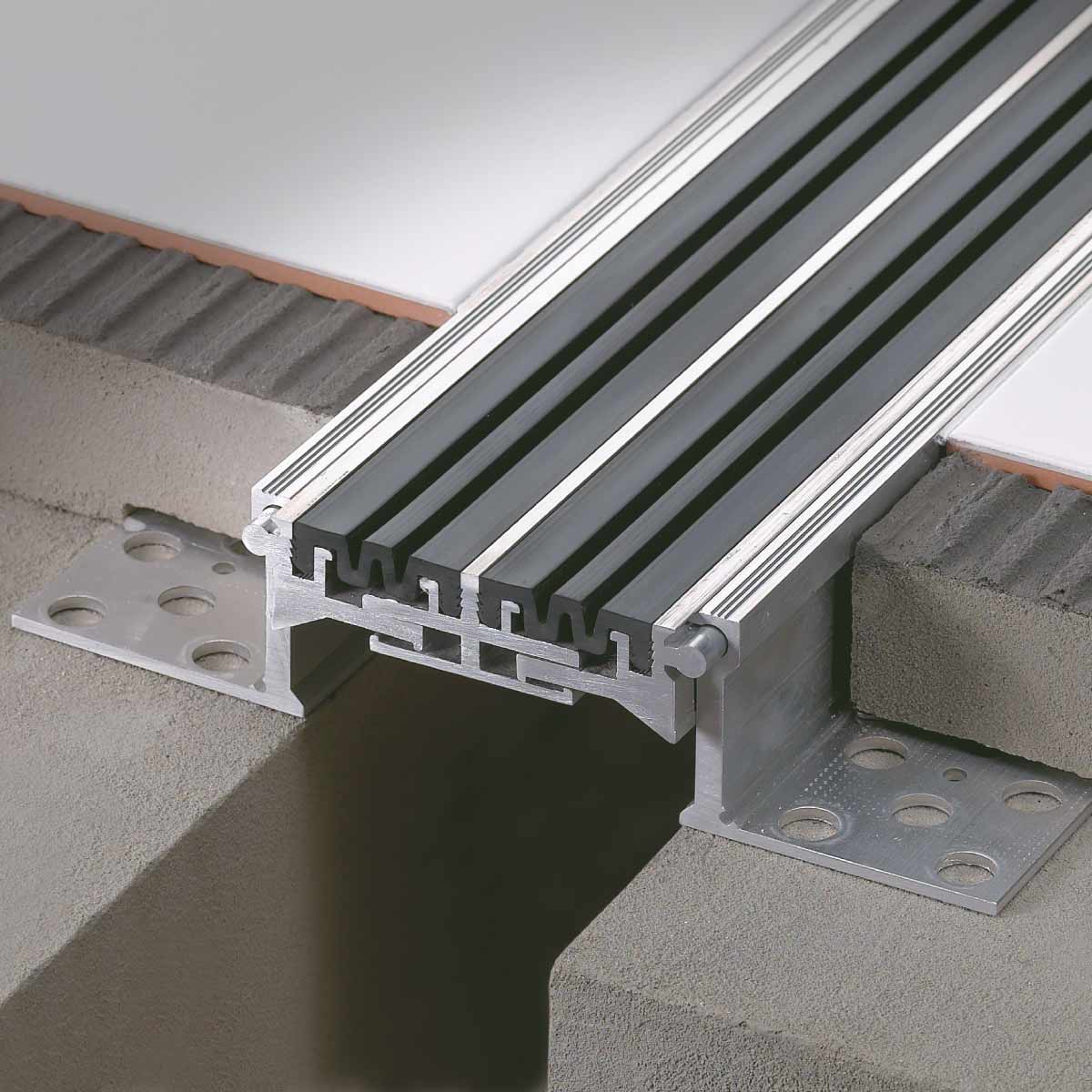

JOINTEC GRM aluminium structural expansion joints are composed of twin metal profiles that allow rotational movement between the metal flanges and the central synthetic rubber insert. Designed to bear loads of large scale buildings or building compounds, they can be installed in the interstitial space between two sections of a building or between two bays. This technical joint links these interspaces, moving three-dimensionally to accommodate a building’s structural and material settlement. The structural bays defined by this profile should be further subdivided with smaller scale movement / expansion joints, chosen according to the expected use and flooring type.

How to install joints JOINTECGRM

INSTALLATION: • Slide the central metal insert into the side flanges. • Snap the synthetic rubber insert into the profile before aligning and positioning the expansion joint on site. • If necessary, protect the rubber insert with masking tape. • Anchor the side flanges with appropriate screws, 30cm on center, on both sides of the profile. • Lay mortar bed over the side flanges, and install the tiles as normal.

-

Jointec GRM-A in Natural Aluminum + Resinprene Insert

Profile Width = 4-9/64’’ (105mm), bridges a 3-1/2’’ (90mm) gap. This extruded aluminum profile offers good resistance to chemical and mechanical stress and wear. The 1-15/32’’ (37mm) - wide rubber insert guarantees high elasticity. Brass profiles are recommended for outdoor use. Ribbed or smooth versions of the rubber insert are available upon request.

Aluminum / Natural

BxH (in) Art. Color 4-9/64x2 GRM 500 AN23 Embossed Cement Grey 4-9/64x2-3/4 GRM 700 AN23 Embossed Cement Grey 4-9/64x2 GRM 500 AN51 Black 4-9/64x2-3/4 GRM 700 AN51 Black

Select items and add them to the quotation list

Select the product to request a quote

| Article | Material | Finishing | Color | Installazione | BxH (in) | |

|---|---|---|---|---|---|---|

|

|